Warning Labels: Things You Need to Know

What are Bar Code Stickers?

Barcode stickers are often used in retail stores to label and organize products. But, the bar code stickers can be used more than organizing products. The bar code sticker is a cost-effective solution. It allows you to identify your products without marking them with ink or other inks.

A barcode is made up of horizontal black lines separated by white spaces. The black and white stripes are read when a scanner passes over a bar code. The scanner then converts these lines into equal numbers. It decodes them, and finally converts them into letters or text.

A barcode sticker is a label you can print that includes a unique, machine-readable code. The code can be linked to your website, product, or service. It's used to identify your business and products.

The first thing to know about barcode stickers is they're not the same as barcodes. Barcodes are codes used by retailers and manufacturers. They used it to track products (for example, in warehouses). A barcode sticker is an adhesive label with a unique code printed. It's usually placed on the back of your product packaging.

Anyone who scans the label with an app can access more information about your company and products. When people check barcode stickers with their smartphones, they can view additional details about your product or service.

This information might include price and availability. As well as customer reviews, videos and photos, and other content related to your product. Barcode stickers help customers learn about products. It makes purchasing decisions based on their preferences. They also provide valuable information for manufacturer inventory management systems.

Why use barcode stickers?

Barcode stickers have been used for various applications over the past few decades. Currently, major retailers and consumer packaged goods companies use them. Primarily to track product movement in and out of the warehouse.

Barcode labels' printed numeric codes—called Universal Product Codes (UPCs)—are easy to scan. It requires no batteries, lasts a long time without wearing out, and varies in height and width according to need. It can be printed in any location on the package—even on curved surfaces like soda cans.

Barcode labels are often produced with two or more different barcodes on each title. Allowing many packages to be linked to one another during a single scan. Barcode labels are designed for durability and longevity. This means that a single scanning device can capture information for thousands of products before the labels need to be replaced.

Once barcode label information is entered into a computer system, it can be accessed from various locations throughout the company and integrated with other databases.

Use barcode stickers to add a professional touch to your shipping stickers. Dark, matte-color bars and numbers are scannable with most modern shipping systems. The white background allows high visibility against any shipment. The rounded corners of the stickers match all industry specifications. It also comes in various sizes.

Who can benefit from barcode stickers?

Barcode stickers are necessary for anyone running a business that accepts credit cards. They not only protect you from possible fraud, but they also give you the ability to track your revenue and expenses. This simple transaction item makes bookkeeping more accessible than ever before.

Barcode stickers are ideal for branches and services where stocks are regularly updated. Barcode labeling helps ensure that the branch staff takes out the correct stock. This prevents mixing up with other supplies being brought in by a delivery driver. It also makes it faster for the team to receive inventory from the driver without leaving the car.

Barcode stickers can be used anywhere you are trying to communicate a message, offering, or item number to someone not physically there. If a pharmacy wants to advertise a new product to pharmacists, barcode stickers will be put on the pharmacist samples and magazines. Barcode stickers and ribbons are used regularly at trade shows. As well as conventions where many attendees cannot attend every event.

1. Barcodes are inexpensive

Barcodes are inexpensive and an excellent way to track inventory items. This can benefit a company because it helps with efficiency and productivity. It is essential to note there are disadvantages associated with ID technology. That includes the inability to read damaged barcodes and update codes.

As barcodes slowly become obsolete, they are becoming passé to consumers. When they scan the item, they cannot read the item's description. Thus, speed up transaction time by reading at check out and not having them wait for the item description to come up.

When used correctly, barcodes allow you to obtain valuable information. As well as reduce errors, and create a streamlined process. A barcode has three parts: A start character, all numeric data, and an end character. Barcodes can be read by both laser and CCD scanners. Though most mobile devices use laser scanning to read barcodes.

2. Barcode Stickers Make Labeling Easy

Barcode stickers make labeling easy. But, the correct type of label can also save you money. The wrong kind of label can cost you money. That's why it's essential to carefully consider each label you use and the type that best meets your needs. With barcode stickers, you get a variety of labels with unique features and uses.

They are available in a wide range of sizes, colors, and shapes to be used in many different situations. Here is a look at some of the most popular types of labels and some tips on choosing the right one for your needs.

Product Identification Labels are often used on products shipped from one location to another. They may also be used for items that will not be moved from where they are placed until they are sold or used by the customer. These include produce, meat, fish, or other perishables. As well as medicines, chemicals, and equipment that cannot be easily moved once it is in place.

Product identification labels provide detailed information. Such as where the product came from and its contents. This includes everything from ingredients to how the product should be handled before purchasing or using it.

Barcode stickers allow you to label multiple items in the same consistent fashion. Barcode stickers are generally used to tag goods, articles, or objects in a large batch of goods. Such as the stock of a sales department or supermarket. Companies use the bar code numbering system called "Industry bar code" (or EAN 13 for Europe).

Bar codes explain each product's price. But inventory tags provide specifications about the usage. As well as the expiration in an accessible format that is cataloged for future reference. The uses for bar codes were not widely enforced until the 1980s. When supermarkets found it more convenient to simply check out faster.

Barcodes allow you to scan the items rather than input them manually into the register. By viewing the specific information on each product, companies can administer their products better. They can also supply more accurate sales reports.

3. Bar codes come in different shapes and sizes

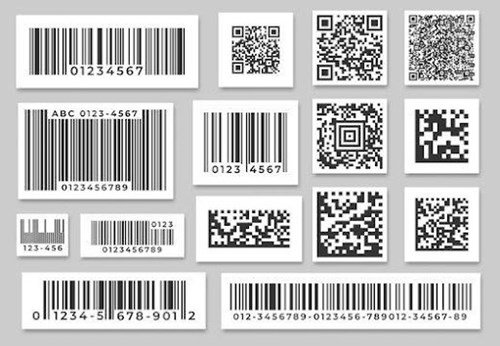

The most popular bar code size is the linear barcode, which scanners can read from at least 18 inches away. This type of barcode is also referred to as the 1D barcode because it only has one dimension.

The type of barcode is dependent on what it will be used for. Understanding the different kinds of barcodes can help you make a better decision. That is when purchasing a printer for your business or looking to buy a scanner for home use.

Type 1 – Standard Universal Product Code (UPC)

A UPC bar code starts with two numbers that indicate the product type. For example, 29 means that it is a food product. Then 12 digits represent the manufacturer number and the specific product number.

Type 2 – Reduced Space Symbology (RSS)

An RSS barcode starts with one number that indicates what type of product it is (for example, five means that it is a drug). Then it has four numbers to represent the manufacturer. The 12 digits represent the specific product number.

Type 3 – Two-Dimensional (2D) Matrix Code

This bar code consists of black lines arranged in a square pattern on a white background. It can hold up to 4,000 characters of information but only takes up 1/10th of an inch on an item's surface.

4. Barcodes need to be printed correctly

Bar code technology has been around for several years. It has become an integral part of the retail industry. It makes it easy to track inventory, process orders, and otherwise streamline operations. If you want to get the most from your packing materials, don't forget to include a barcode on each item you sell.

As a small business owner, you probably don't spend much time thinking about bar codes. After all, they're pretty standard stuff these days — at least for physical products. But if you're printing barcodes for your online store, it's essential to pay attention to some details.

These look easy enough to generate by computer. But they're more complicated than they seem. Many individual components need to be perfectly aligned. If one digit is off by even one space, it can throw off the entire reading.

Even when you have a perfect bar code image on your computer screen, there's still a chance that something will go wrong with the printing process. This happens most often when the ink used in printing is smeared or blurred.

This can happen because of printer problems or insufficient paper stock. The symbol won't scan when this happens, and your customer might be unhappy with your product.

Incorrect bar codes can cause products to be rejected at the checkout counter. When it comes to scanning the correct barcode, many factors can cause an item to be misread by a scanner. Dirty scanner lenses and incorrectly positioned bar codes can be the cause of this. Incorrect bar codes are one of the biggest reasons for rejected items at the checkout counter.

There are two basic types of barcodes when it comes to scanning: linear and 2D. Linear barcodes make up the traditional 1D matrix code that most consumer goods today. 2D bar codes are gaining popularity due to their ability to hold more data than a linear barcode. With 2D barcodes, there is more information about an item encoded within each symbol.

When a piece of merchandise is scanned at checkout, the cashier can immediately access extra information. Such as price and product description. For this information to be recorded accurately and quickly, specific guidelines must be followed. That is when printing 2D barcodes and placing them onto your product labels.

5. Not all barcodes are the same

Everyone knows what a barcode looks like. They're everywhere, on everything from shampoo bottles to cereal boxes. Trying to imagine a world without them is a little tricky. But, it's not too difficult to imagine a world without the identical barcodes that we have today.

All barcodes look the same to our naked eyes. Barcode scanners, however, can distinguish between the different standards. They use a light source and a sensor to record the pattern of dark and light lines in the barcode and translate it into numbers. What makes one barcode different from another is the type of symbology used.

More than 80 different types of symbology are recognized by the GS1 System, an international code that creates a standard for identification across industries. In addition to generic two-dimensional (2D) barcodes such as UPC-A and UPC-E, there are stacked codes such as Code 128 and Interleaved 2 of 5. The type of code used depends on the industry. For example, airlines use Code 128, automotive use PDF417, and drug companies use UPC/EAN.

The barcode you use on your product packaging can profoundly impact your sales. There are various barcodes, and many are not compatible with the technology in a customer's phone or tablet. If you don't use the correct barcode, the customer may have trouble scanning it, which means they won't add your item to their shopping cart, and they may lose interest in the item.

Even if the consumer can scan your barcode, it might not be read accurately. Barcodes are designed to be read by machines, not humans. This can lead to problems that make customers frustrated. It can leave them with a negative brand experience. The most common issue is an error message saying the code can't be read because it is damaged or printed incorrectly. Even with careful printing of barcodes, this problem affects nearly one in three packages.

Conclusion

Barcodes are increasingly crucial in everything from retail stores to libraries. But what exactly is a barcode, and why is it so helpful? Let's take a look at how these codes work and where you're likely to see them. Barcodes are made up of lines — like the stripes on a bar of soap — that represent numbers in an agreed-upon format. When you scan a barcode, you're reading off those numbers and translating them back into text or numbers.

Barcodes are simply a machine-readable representation of information about an item and its owner. The barcode itself is an image that a scanner can read. Most barcodes use black bars to form numbers, with additional lines of white space to separate them. Using a combination of black and white, UPC barcodes (Universal Product Code) can use up to 12 digits to represent the identity of an item and its manufacturer.

Scanners come in many different shapes and sizes, but the fundamental principles remain the same. A light source reflects off the surface of the barcode, which is then analyzed by an optical sensor. The scanner converts this light into electrical impulses, which are then translated into numbers, making it easy for computers to understand what you're trying to scan.

Barcodes may seem like a thing of the past, but they're still essential in the modern world of eCommerce. Barcodes allow retailers to track inventory more easily and quickly. One study found that 43 percent of retailers were using barcodes for inventory management to some extent and that their use had gone up from the previous year.

Trying to manage inventory without barcodes is an incredibly manual process. You have to take each item out of stock, count it, then put it back if you want to make sure you're not losing anything to theft or damage. Barcodes simplify this process by allowing retailers to scan items as they come into stock and recheck them when they go out for sale.

Barcodes are also helpful in preventing shoplifting. By scanning a customer's items as they leave the store, you can ensure that nothing gets stolen, reducing your costs and increasing customer satisfaction. Barcodes can even help you avoid losses due to damages while in-store.

When customers pick up products, you can scan them and check them against what the customer took off your shelves. This prevents double-counting and stops people from walking out with items that don't belong to them.

Barcodes are a vital component in many different industries. From logistics and retail to healthcare, barcodes are used to track, identify and organize all sorts of products. They're also commonly used for inventory management and give customers fast, easy access to information about products.

The International Organization for Standardization (ISO) developed barcodes in the 1970s as a way for retailers to distinguish between different types of products so that they could quickly and accurately track inventory.

The organization went on to create an entire set of standards for how barcodes should be made, including details like how tall the bars and spaces should be, the type of 'check' character included at the beginning of each code, and how the codes should be oriented concerning one another.

Barcodes can be read by either a laser or an imaging scanner. The scanners that use lasers are known as 'imagers.' In contrast, those that use light-emitting diodes (LED) are called 'flashers.' Both types of scanners have their benefits and drawbacks, with imagers having a more extended range and flashers often being more cost-effective. Today, most retailers use flashers because they're both less expensive and more practical for everyday use.

Get your barcode sticker now at West Coast Label in Singapore!

Barcode stickers are often used in retail stores to label and organize products. But, the bar code stickers can be used more than organizing products. The bar code sticker is a cost-effective solution. It allows you to identify your products without marking them with ink or other inks.