Warning Labels: Things You Need to Know

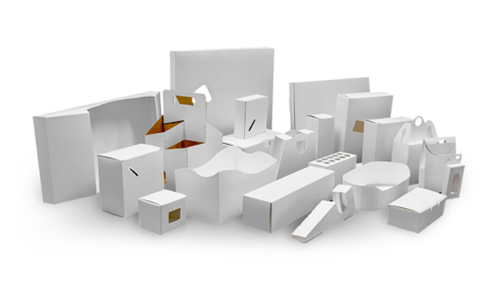

Box printing is one of the most common processes used by manufacturers of labels, cartons, and boxes. Compared to other printing processes, the limitations are great. This is because of its color and quality, texts, and even materials that can be printed on.

Trying to find the right box printer for your project can be overwhelming. After all, so many variables go into choosing a box printer. The size of your order, the type of application, the surface it will be printed on (foil, paper, or plastic), quality of the print (full color vs. spot color), and turnaround times are just some of the factors that you must consider when picking a box printer.

Before getting overwhelmed, Let’s take a look at what box printing means.

What is box printing?

Box printing is one of the oldest printing methods still in use today. It is also known as offset lithography. This type of printing is also called the four-color process; however, only colors are used. If a full-color image is required, then it is done through the process of overprinting, which means colors are printed over each other on the press. Similarly, if spot colors are required, then they are printed individually.

This type of printing method has been in use since 1875, and still, it is prevalent among many businesses because of its speed and cost-effectiveness. Box printing is also creating realistic, eye-catching graphics on corrugated cartons.

These graphics are often used to show off food and product packaging and create custom product boxes. Whether you're a big brand or an individual seller, custom box printing is a great way to stand out from the crowd and make your products more attractive.

Why use box printing?

Boxes are handy for both storing and transporting items. They are commonly used to store books and other things that need protection from dust or moisture. Boxes made from corrugated fiberboard can also protect fragile items during shipping.

Many businesses use this type of printing to make boxes easy and affordable for mass production. When choosing a box printing solution, there are several things to consider.

But why use box printing? What makes it different from other printing methods? Here are five reasons you should consider box printing:

- Durability – Boxes are made with sturdy paperboard, so they're able to hold heavier items without bending or breaking.

- Low Cost – Boxes are almost always cheaper than other types of custom packaging because they don't require unique materials like metal, glass, or plastic.

- Environmentally Friendly – Boxes can be reused as many times as you want without losing their shape or quality. When you're finished with them, you can recycle them instead of throwing them in the trash, where they may end up in landfills.

- Versatility – You can use boxes for virtually any type of promotional material, including clothing, food, or electronics and virtually.

Different types of packaging boxes

1. Corrugated boxes

Corrugated boxes are required when shipping more oversized items to your clients. Corrugated boxes are packaging materials used to protect and transport goods. Made from a fluted paperboard core, corrugated boxes are often made from recycled paper fiber. This is because they have high strength-to-weight ratios.

They are typically made of either single or multi-layered sheets of corrugated fiberboard, an essential material in packaging. Corrugated boxes are the workhorse of the shipping industry. They are designed to be lightweight, waterproof, and sturdy. The shape of the box is a crucial factor in whether they arrive at their destination in one piece.

The structure provided by corrugated boxes also allows for more efficient use of space, which is ideal when shipping items cross-country or overseas. They can be used for small and large items and are sturdy enough to withstand the wear and tear of being shipped from one place to another.

Corrugated fiberboard consists of three layers: two outer layers of fluted paperboard, which provide stiffness and strength, with a corrugated sheet in the middle. The corrugated board has similar properties to duralumin (aluminum) in that it combines high strength with low weight.

Corrugated boxes are made from a fluted corrugated plastic sheet bonded to two flat sheets of paperboard, creating a container that can be used for shipping virtually anything.

To select the correct corrugated box for your shipment, you must first consider its strength - how much weight it can hold before buckling or breaking. The box's grade designation number represents the weight capacity.

For example, an E-flute grade box has a capacity of 200 lbs, while a C-flute grade box has a capacity of 50 lbs. When choosing an appropriate grade of the box, keep in mind that if you put too much weight on it, it will certainly collapse and possibly damage your shipment.

Here are the three major types of corrugated boxes:

Flat-Bottom Boxes: These boxes have two panels and a flat bottom. They're great for shipping heavy items and larger-sized products. If you're sending something that needs extra protection from rough handling, these are the best option.

Gusseted Boxes: Gusseted boxes are similar to flat-bottom boxes, but they feature triangular flaps on each side that allow them to expand as needed. They're ideal for bulky products or smaller objects that need extra support in transit.

Double Tuck Boxes: Double tuck boxes have two tucks on each side, allowing them to expand with your product inside. These are the perfect choice for irregularly shaped and lightweight products alike. Plus, they look great!

2. Aseptic cartons

Aseptic cartons are widely used for milk and beverage packaging. The milk carton has been used in the US since 1934, although it is no longer commonly used in most parts of Europe.

The carton is made of paperboard and consists of three layers:

- An outer layer (the cover)

- A middle layer (the body)

- An inner layer (the liner)

The outer layer is printed with details about the manufacturer, product, etc.; the inner layer may be colored to show different flavors or varieties. The middle layer can be printed with nutritional information or advertisements.

There are three elements in aseptic packaging:

Flexible film is the outer layer that protects from external elements and provides a waterproof barrier to oxygen and water vapor. It is typically made of polyethylene.

The inner layer is a foil-polyester laminate film.

The laminate effectively forms a barrier between the milk and the surrounding atmosphere, preventing oxidation and bacterial contamination. The foil acts as a moisture barrier, while the polyester layer functions as an oxygen barrier.

The core is where milk is held. It can be made of several different materials, depending on the manufacturer. Some common materials include paperboard or extruded plastic, which can be formed into trays or bags for holding milk. Cardboard cartons are being used more frequently because of their environmental friendliness over plastic alternatives, but they are more expensive to manufacture than plastic.

Competition in the aseptic carton industry is primarily based on price and quality. The primary price factor is the cost of paperboard. Suppliers have developed a different approach to this challenge: they have invested in new technologies allowing them to use less virgin fiber while maintaining a high-quality package.

Aseptic cartons are made from recycled, post-consumer paperboard. This has contributed to an increase in demand for recycled fiber. Also, it has created many opportunities for suppliers of recovered paperboard.

3. Boxboard cartons

Cardboard is an ideal packaging material for moving your stuff, but plain old cardboard boxes won't do when you're moving your delicate belongings. You need to protect them with sturdy and protective packing materials like bubble wrap, packing peanuts, and crumpled paper.

Boxboard cartons are a versatile packaging product that can be used for a wide range of products. They are solid and sturdy, yet lightweight and easy to handle. These cartons are made from paperboard and offer good impact resistance and excellent formability for easy shipping and storage.

They are manufactured from quality raw materials like corrugated board and kraft liner board, which provide superior strength and durability, and can be customized to meet different needs. The material used in these boxes is highly recyclable, and the boxes can be easily flattened for quick recycling or disposal when they are no longer needed.

Moreover, they are available in different sizes with strength levels ranging from 200 lbs to 1,500 lbs. Boxboard cartons are also lightweight compared to other packaging materials like corrugated cardboard or wooden crates and hence easy to handle by a single person.

A boxboard carton can be used to protect a range of items depending on their size and shape. If you have delicate items that you wish to transport safely and securely, a range of smaller boxes may be ideal. Alternatively, suppose you have more oversized items that need protecting. In that case, larger size cartons will offer a sturdier solution as well as be able to make efficient use of your space.

4. Gable tops cartons

Gable top cartons can be used for both liquid and solid products. They are the most popular of all cartons because they allow you to see the inside contents. They are made with a large bottom, holding up to 25 pounds of product, while the lid can display a label or other graphics.

These cartons do not collapse easily, making them easier to stack and store. Gable top cartons are also commonly used as a clamshell, which means that they have a hinged lid that can be folded in half and then secured with staples or glue.

Gable top cartons are not often recycled because they cannot be flattened like other options. The lids are usually made of paperboard, which is recyclable, but the plastic film on the sides makes them non-recyclable. These cartons can be used for food products such as meat, fish, and produce.

By understanding the benefits of gable top cartons, packaging designers can create a more appealing and memorable package than other packaging types, such as boxes.

Tops of gable top cartons are generally constructed from two pieces of paperboard (such as white corrugated) that form the front and back panels. The panels are then connected near the bottom with a hinge to open the front panel.

The hinge is reinforced by a brace or "ears" at the top of the box. When designing gable top cartons, the hinge must withstand substantial stress without being damaged or breaking.

The strength of the hinge will be tested when the box is filled with product, causing it to bend under pressure. It is also essential that hinges do not leave marks on the product or cause damage if they contact it during transportation. There are many different options for hinge designs, including metal hinges, plastic hinges, tape hinges, and others.

5. Eggs cartons

If you are a regular egg-eater, you should know that it is possible to reuse the plastic cartons from your eggs. You can wash them and use them again to store food items or other uses.

The eggs come in various sizes and colors to buy the proper carton for the right product.

If you want to store more than one small item, you can reuse the storage carton of an appliance.

Also, instead of throwing away empty egg cartons, they can be used as seedling containers for growing plants. You may want to make holes on both sides of the carton before planting seeds inside it.

This way, your sources will get a sufficient amount of light and moisture. If you do not want to spend money on buying pots for your plants, you can use the egg cartons instead.

There are many different ways to package eggs. Some are more suited to transporting fragile eggs, while others provide better protection from day-to-day handling.

How do you choose the best packaging for your eggs?

The answer all comes down to how you want your eggs to arrive at their destination.

When you want to protect them:

You'll need a box that can withstand the vibrations, shocks, and bumps that come with every journey. It would help if you also used a carton to keep out moisture, dirt, and pests. Finally, the box will need a lid that closes securely and is easy for the delivery driver to open.

When you have time constraints:

You'll probably know exactly where your eggs are going, so you can make sure that they don't spend too much time in transit. In this case, the most important thing is that your cartons fit neatly into the van or truck and don't get damaged along the way.

When you're looking for less waste:

You might want to use a smaller, lighter box than usual so it's easier for customers to carry home after collection.

How to Select the Most Appropriate Printing Method for Custom Boxes

Flexo:

Flexo Printing is a quick and cost-effective way to print your boxes. Flexo printing is the most popular method of printing on corrugated boxes. It involves applying pressure to the box's surface while it is moving through a press. A smooth inked plate transfers the design to the box and creates a rich, deep, vibrant image.

Using flexo printing to decorate and print your boxes is a very cost-effective way of marketing your product. It ensures that your customers will remember you and remember your brand name.

This is particularly effective if you are selling a product used in an office or a school or selling a product for children. The logo's colors will easily distinguish your boxes from other boxes and can be printed on the side of the box.

Litho:

Litho printing for boxes is one of the most beautiful ways to showcase your product. It is a form of commercial printing that gives your product a professional look.

Generating high-quality litho printed boxes for products is not easy, but the results are worth it. These boxes make the products attractive and appealing to the customers. Litho printing for boxes has become popular because of its unique features such as high-quality display, durability, anti-scratch, and waterproof quality.

Litho printing for boxes is a durable, affordable option for businesses with heavy-duty packaging needs. Litho printing is a commercial printing that uses a flatbed press to print on large sheets of paper or cardboard. The printing process is called lithography, and the finished product is called litho stock.

Digital:

If you sell boxes, envelopes, or other packaging components, then digital printing is a great way to save money and expand your business.

Digital printing is a form of electronic printing that uses computer technology to produce high-quality graphics and text for marketing materials like brochures, leaflets, magazines, business cards, and catalogs. The overall process consists of four steps:

- Preflighting (preparing files for output)

- File preparation (creating files)

- Output (printing)

- Post-press finishing (envelope addressing)

The process of digital printing allows you to print a wide variety of items with the same equipment. This saves time and money. Plus, it will enable you to create any design you want for your packaging. There is no need to worry about minimum order requirements to create one-off designs on the spot.

Conclusion

Whether your business is small and start-up or a large-scale business, there is a good chance that you will probably need to do some form of printing. Whether for marketing materials, stationery, packaging, or even for your product itself, personalized box printing is an excellent way to stand out from the competition.

There are several ways in which customized packaging can assist in your marketing efforts, such as:

Creating brand recognition

Setting you apart from competitors

Encouraging further sales and purchases

Improving customer loyalty

Printing on boxes is one of the most cost-effective ways to promote your business, product, or service. Box printing offers a choice of materials and finishes, which helps you create a real impact for your brand. As well as being eye-catching, printed boxes provide excellent protection for your products. They can be used for storage, marketing, or simply as retail packaging.

A company's brand image is everything when it comes to selling products, and nothing will make a better impression on customers than a beautifully designed box. The proper packaging can increase product sales by up to 40% and save consumers time and money.

Box printing is a process that involves the use of boxes and various printing techniques, such as offset printing, flexography, and lithography. A box is used to print on paper, plastic, cardboard, and other materials in rolls. Box printing is more versatile than any other printing technique because of the many different boxes available for consumer packaging.

The most common type of box printing is when you have a package with pictures and words. This type of box is done through offset printing because so many colors are involved in the process.

Boxes are more than just a container that holds a product. They are also crucial as they are often among the first contact points between your business and customers. Boxes act as carriers of information, encouraging consumers to choose one product over another based on their own needs and requirements at the time of purchase.

If you want to have your box costumize never hesitate to contact West Coast Label, one of the best printing labels in Singapore for your brand!

Box printing is one of the most common processes used by manufacturers of labels, cartons, and boxes. Compared to other printing processes, the limitations are great. This is because of its color and quality, texts, and even materials that can be printed on.